Repair Cost Oversight

Reducing component repair expenditure

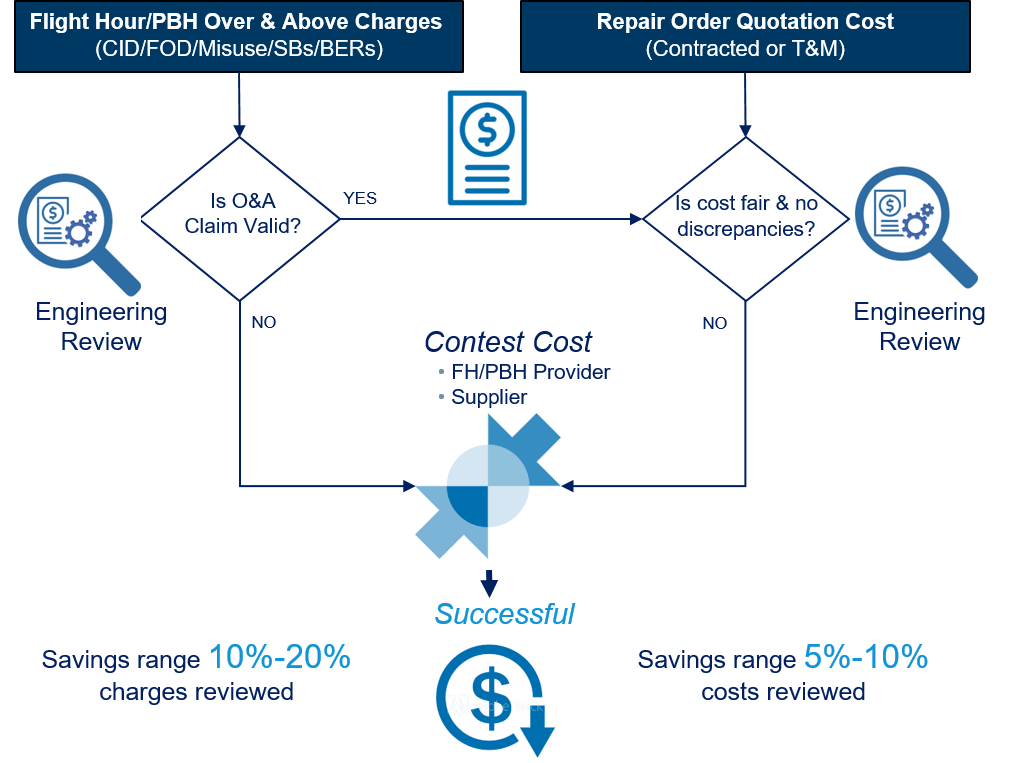

Repair Cost Oversight Process

Value Proposition

- Our services are proven and are delivered by a highly experienced and dedicated engineering team

- We utilise a range of bespoke tools and techniques to enhance detection of cost discrepancies and opportunities to reduce cost

- Our unique data warehouse provides our engineers with millions of reference benchmark repair data records

- Our service fee structure is Risk Free – No savings/No fee.

- Where successful and a saving is achieved, a gain share percentage is charged – delivering customer a ROI 3x-5x

Cost Oversight – Component Flight Hour Over & Above Charges

- Component flight hour (‘PBH’) agreements include over and above (“O&A”) charges related to CID/FOD/Misuse/SBs/BERs

- Charges can be subject to erroneous O&A claims and excessive repair costs

- An airline’s total annual flight hour costs can include an estimated 5%-15% O&A charges

- We ensure, as far as possible, that an airline only pays for applicable and fair repair charges

- Our engineers assess if charges should be included under the flight hour rate, e.g. not CID but normal wear and tear, or confirm O&A classification is correct and then check the repair cost is fair and equitable

Cost Oversight – Repair Quotations

- Supplier repair costs, including contracted pricing, can be subject to errors and overcharges

- The service is applicable to high/medium value repairs – e.g. APU Thrust Reversers, Cowls, Landing Gear Flight Surfaces, Engine accessories and high component/rotable repair costs (≥$5k)

- Our engineers review quotations to ensure repair costs are fair and equitable versus the component defect the proposed supplier workscope, and fully meets any contracted repair pricing terms

- Our engineers police and enforce contracted T&Cs and pricing, and the validate warranty denied quotations